What counts is the projection of the neck or fingerboard surface at the bridge, which sets the bridge height. The angle that makes that come out right is not important in itself, IMO. When you're making by hand there are lots of things that can change that angle, and you just have to fit it on every guitar.

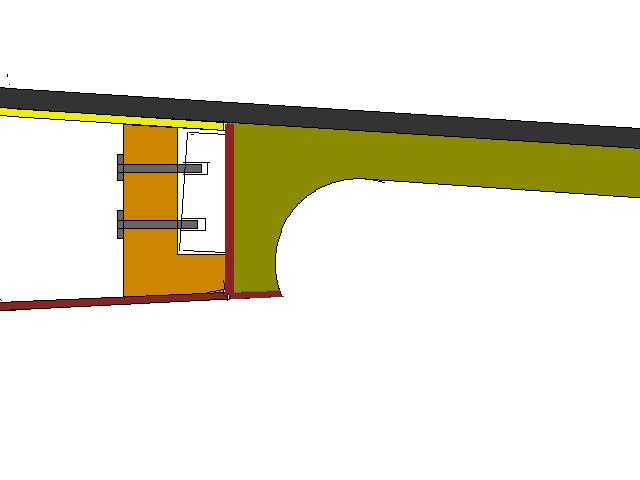

Assuming that you use a 6mm thick fingerboard, and that it's not glued to the neck when you cut the joint, it's easiest to go by the projection of the surface of the neck itself, sans fingerboard, at the bridge location. I go for a projection that is .5mm above the top.

In my case, I like to glue a wedge under the fingerboard extension rather than trim off the underside of the fingerboard, so that makes the neck end a little 'proud' of the top when everything is fitted correctly.

Fit the shoulder of the tenon, the end of the neck, first, with the dovetail or whatever oversize, so that the neck end sits 'proud' of the top. Trim the surface where the neck hits the side until the centerlines line up and the projection is .5mm higher at the bridge than at the edge of the top, or, as I do it, the upper edge of the soundhole. Then just 'walk' the dovetail down. This way you're only working on one adjustment at a time, which is about all my old brain can keep track of.

|

Thank God you guys are here!

Thank God you guys are here!